Please let me know if my assignments have incorrectly ordered words! Some devices mix up the order of my paragraphs...

5/12/2021

Though many people use the terms ‘crayons’ and ‘Crayola’ interchangeably, crayons have existed long before the company came to be. Crayons, however, were originally either too expensive for the common classroom, too poor in quality to be used for long periods of time, or potentially toxic. Crayola made its’ name in 1903 by producing colored, non-toxic crayons for schoolchildren that were sold for about 5 cents (17). Founders Edwin Binney and Charles Harold Smith discovered after much experimentation with compounds that adding carbon black to the crayon mixture would make the crayon both more durable and more vibrant in color compared to other crayons at the time (17). But like many objects found daily, people do not tend to think about the process and work taken to create these common items. In creating Crayola crayons, the process is generally simple thanks to modern-day technology, though obtaining the materials needed is still a complex process.

To understand the social and environmental impact of obtaining and processing the raw materials that make up our everyday items. In other words...all this stuff we use, eat, wear, apply, drive.... This knowledge will hopefully inform our choices of what items and manufacturers we wish to patronize out of respect for humanity and the health of the planet.

The "I, Pencil" reading and the artists from Silent Beaches have inspired this assignment:

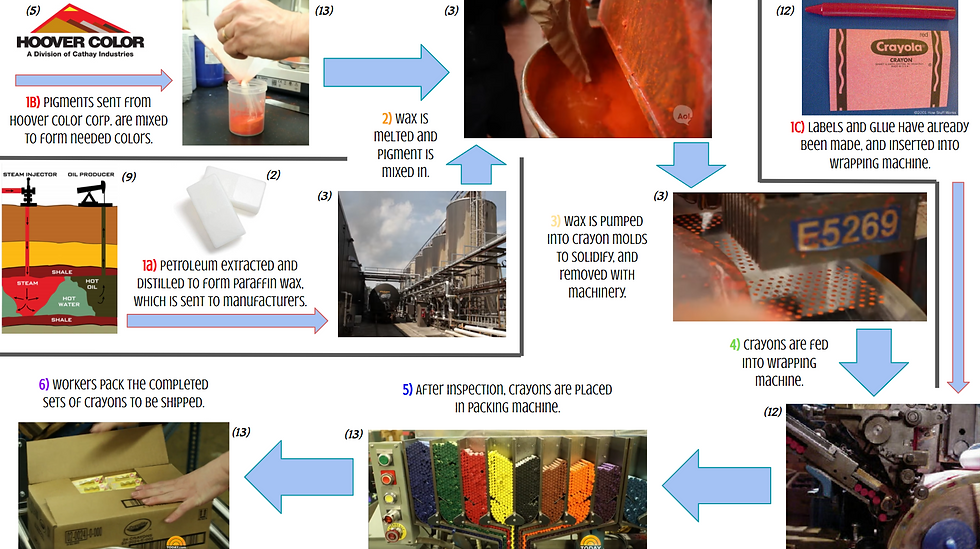

According to the official website, “Crayola Crayons are made primarily form paraffin wax and color pigment.” (4) Although other trace ingredients are used, they are not specified. Paraffin wax is a cloudy-white wax that is obtained from crude oil, specifically petroleum (15). Petroleum found in states such as Texas, Alaska, California, Louisiana, and Oklahoma (9), where the location is first studied to determine the ideal spot to start drilling. Due to the underground pressure, oil emerges rapidly and is collected. Companies also inject water/steam, chemicals, or reinject the natural gas that emerges with the oil to raise the pressure required to extract all the petroleum (9). It should be noted that petroleum extraction can cause large disturbances to the ecosystems present and to the land through the drilling and injection processes. Petroleum must be refined once it is extracted in order to be used. By exposure to high

(9) Oil refinery

temperatures, the oil separates into fractions. Because paraffin is a hydrocarbon that composes petroleum, the fractions can be distilled to separate paraffin from the general petroleum product. While the petroleum product is taken, the distilled paraffin wax is de-waxed and de-oiled to be used (11). The wax is then ready to be shipped to the crayon factories. Once delivered, the wax is pumped into supply tanks that store it until needed. Color pigments are created from water and oil through chemical reactions. Chemicals are mixed, and water is extracted to produce a solid product (11). The product is dried, crushed, and blended to create the pigment powder used by Crayola. Crayola’s pigments come from the Hoover Color Corporation in Hiwassee, Virginia (11). Hoover Color’s pigments include iron oxide “…which are either mined or produced synthetically, and they offer the added benefit of being the result of an

environmental restoration effort,” (8). The powders used for the crayons are determined by the Research and Development team at Crayola. In the lab, they mix different colored pigments to create the specific shades of the crayons (13). The final powders are tested before being used in mass production by making a small batch of crayons that created, used, and tested for their strength and color consistency. Crayons are also not complete without the paper wrapped around it, identifying what specific color it is. Although there is no officially released information about where and how the papers are made, we can infer that the labeling paper is made similarly to sheet paper. The ink used to print the name and classic design of the crayon is also unrevealed information, but we can infer that the

(13) Different pigments from Hoover Color Corp.

creation process is similar to the creation of colored pigments. As stated in an article about the inking pigments, pigments are defined as “…any particulate insoluble solid-colored, black, white, or fluorescent that alters the appearance of an object by the selective absorption transmittance and/or scattering of light,” (1). Certain chemical reactions are needed to produce not only the ink, but the black color used for labeling. Finally, the glue used to bind the labeling paper is made from water and a non-toxic cornstarch, which was a decision made due to the possibility of children potentially consuming the label (12). With these different process and products produced, the manufacturing of the actual crayon can proceed.

(6) Solar farm for solar power

(3) Rotating crayon mold

The production of crayons from the base materials is heavily dependent on machinery. Paraffin wax is brought to factories from rail cars or trucks (16) and is pumped into storage tanks. When production begins, the wax is sent to kettles to be melted (paraffin wax melts at 120-150 degrees F (14). Workers

also add color pigments during this stage. Once it is fully melted, the wax is pumped into a rotating crayon mold. After the wax solidifies, the crayons are pushed out of the mold and extracted by a mechanical arm that delivers it to the labeling machinery (16). At this stage, the labels have already been inked and premade (information about Crayola labels are not released to the public) and are ready to be wrapped. As the crayons are fed into the machine, the cornstarch-glue is ready in a slot where the crayon enters. The paper label is then pressed against the glue and wrapped twice around the crayon by a roller (12). When the crayons emerge fully wrapped, they are inspected to make sure there are no damaged ends. Rejected crayons are removed and re-melted to be

remade into a better-quality crayon (7). Acceptable crayons are then sent to be packaged. As with the manufacturing process, all crayons are kept separated by color and are fed into various machinery that packages them depending on the size of the package/box, which can range from 2-96 crayons per time (12). The

crayons are individually filtered into narrow lanes that are removed one at a time each time a new box is filled (13). The completed boxes are then packed by workers to have them shipped to different destinations, such as stores, restaurants, or other companies. Something we must additionally recognize is the cost of crayon production, especially considering how 3 billion crayons are produced per year (4). Thankfully, Crayola has used eco-friendly sources for power since its beginning in 1903. Water power was the original source for production, which later turned to solar power in 2010. And since 2020, Crayola has been using 100% renewable energy for manufacturing their products (6). Labor practices are also to be considered when thinking about production, since workers are also crucial to the manufacturing process. According to the Hallmark and Crayola Supplier Code of Conduct, child labor is prohibited, younger workers are

cautiously protected, and discrimination in the hiring process is prohibited (10). Working hours are managed acceptably and payment is also distributed fairly. The working environment is also kept environmentally and physically safe, so that no health hazards or harassment/abuse is carried out. The health and safety of the workers is also acknowledged and provided for, such as with pregnancy (10). Overall, the environmental and labor practices are well tended to in order to protect both the environment around them and their workers.

Similarly to the “I, Pencil, My Family Tree” article, the creation of Crayola crayons is often overlooked because it is so commonly used. Something as common as a crayon has a complex path of collection and creation in order to gather the necessary materials and manufacture the product. We also don’t often think about who is involved in making the product and the resulting effects from the process. But once we have are aware of the costs and effects, we can begin to consider what exactly we are buying, and if we can really support what it took to create our purchase. Although there are some potential downsides in the harvesting of some of its raw materials, Crayola is one of the few companies that aims to respect the health of our planet and people, as seen through its power sources and labor practices. With a simple production process and a respectable practice, the Crayola company has made a name for itself that will not be forgotten anytime soon.

(1) Abdelmaksoud, Wael M., Mohamed M. M. Aboaly, and Said M. Taleb. "Synthesis and Characterization of Novel Pigments Derived from Red Lake C." Pigment & Resin Technology, vol. 48, no. 5, 2019, pp. 383-388. ProQuest, https://www-proquest-com.jerome.stjohns.edu/scholarly-journals/synthesis-characterization-novel-pigments-derived/docview/2276806513/se-2?accountid=14068, doi:http://dx.doi.org.jerome.stjohns.edu:81/10.1108/PRT-12-2017-0105.

(2) Amazon.com: Paraffin Wax Blocks - 1.5 Pounds Multi-Purpose ... www.amazon.com/Paraffin-Wax-Bricks-1-5-pounds/dp/B07DMNHQQZ.

(3) aol. “You've Got Crayola Crayons Manufacturing Process.” YouTube, YouTube, 28 Sept. 2012, www.youtube.com/watch?v=srAyApxoRDY.

(4) “Can You Provide Information about Crayons for a Science Fair Project?” Crayola, crayola.com/faq/science/can-you-provide-information-about-crayons-for-a-science-fair-project/#:~:text=Crayola%20Crayons%20are%20made%20primarily,measured%20amounts%20of%20color%20pigments.&text=The%20hot%20wax%20mixture%20is%20poured%20into%20molding%20machines.

(5) Contact Hoover Color, www.hoovercolor.com/index.php/contact.

(6) “Crayola.com.” Crayola, www.crayola.com/about-us/sustainability.aspx.

(7) “Crayon.” How Products Are Made, www.madehow.com/Volume-2/Crayon.html.

(8) ENVIRONOXIDE - Hoover Color. www.hoovercolor.com/images/Sales-Literature/Environoxide-Sheet-Final.pdf.

(9) Fossil Energy Study Guide: Oil. www.energy.gov/sites/prod/files/2013/04/f0/HS_Oil_Studyguide_draft2.pdf.

(10) “Hallmark & Crayola Supplier Code of Conduct.” Hallmark Crayola, corporate.hallmark.com/wp-content/uploads/2019/09/CODE-OF-CONDUCT-9-5-19.pdf.

(11) Hernandez, Chelsea. “Crayons - Design Life.” Design Life- Ycle, www.designlife-cycle.com/crayons.

(12) “How Are Crayons and Markers Made?” HowStuffWorks Science, HowStuffWorks, 2 Sept. 2020, science.howstuffworks.com/innovation/science-questions/question5631.htm.

(13) “Inside the Crayola Factory: See How the Iconic Crayons Are Made.” TODAY.com, www.today.com/video/inside-the-crayola-factory-see-how-the-iconic-crayons-are-made-893853251852.

(14) “Paraffin Wax.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., www.britannica.com/science/paraffin-wax.

(15) Tufvesson, Linda M., and Pål Börjesson. "Wax Production from Renewable Feedstock using Biocatalysts Instead of Fossil Feedstock and Conventional Methods." The International Journal of Life Cycle Assessment, vol. 13, no. 4, 2008, pp. 328-338. ProQuest, https://www-proquest-com.jerome.stjohns.edu/scholarly-journals/wax-production-renewable-feedstock-using/docview/212186677/se-2?accountid=14068, doi:http://dx.doi.org.jerome.stjohns.edu:81/10.1007/s11367-008-0004-1.

(16) “Where Do the Raw Materials for Crayons Come from?” Crayola, crayola.com/faq/your-business/where-do-the-raw-materials-for-crayons-come-from/#:~:text=Paraffin%20wax%20is%20shipped%20to,by%20truck%20or%20railroad%20cars.

(17) Williams, Susan. "WHAT IS A CRAYON?" Design for Arts in Education, vol. 83, no. 6, 1982, pp. 14. ProQuest, https://www-proquest-com.jerome.stjohns.edu/scholarly-journals/what-is-crayon/docview/1296333243/se-2?accountid=14068.